XANTAR™️ LDS (Plating) Grade

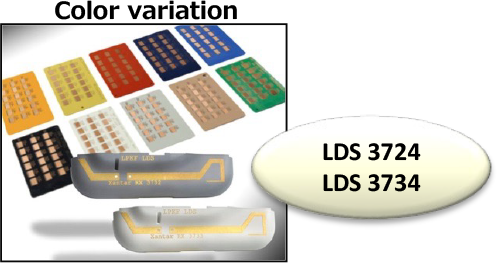

Polycarbonate resin has excellent impact resistance, flame resistance, and dimensional stability. In addition to its application to LDS technology, we have developed XANTAR™️ PC/ABS grade with added chemical resistance and penetration resistance, and XANTAR™️ PC grade with V-0 flame resistance. In addition, we have newly developed high whiteness LDS grade with various colors as a design improvement proposal.

|

|

|

|

|

Puncture strength |

Flame resistance |

High FR |

High Flow |

Chemical Resistance |

|||

|---|---|---|---|---|---|---|---|

|

Properties |

LDS3720 (PC/ABS) |

LDS3724 (PC/ABS) |

LDS3730 (PC) |

LDS3734 (PC) |

LDS3750 (PC) |

LDS3760 (PC) |

LDS3780 (PC/PET) |

|

Color |

Black |

White |

Black |

White |

Black |

Black |

Black |

|

MVR [cc/10min] (260℃, 5kg) |

13 |

13 |

8 |

11 |

14 (300℃/1.2kg) |

28 |

15 |

|

Flexural Strength [MPa] |

80 |

80 |

80 |

78 |

90 |

90 |

75 |

|

Flexural Modulus [MPa] |

2,250 |

2,250 |

2,300 |

2,000 |

2,400 |

2,400 |

2,100 |

|

Strain at break [%] |

>50 |

>50 |

>50 |

>50 |

>50 |

>50 |

>50 |

|

Charpy Impact[kJ/m2] |

NB |

NB |

NB |

NB |

NB |

NB |

NB |

|

Notched Charpy Impact [kJ/m2] |

60 |

55 |

55 |

45 |

60 |

55 |

55 |

|

DTUL 1.80MPa [℃] |

102 |

102 |

122 |

120 |

126 |

103 |

|

|

Dielectric constant (ε’) 1GHz |

2.80 |

3.00 |

3.00 |

3.10 |

2.80 |

3.00 |

|

|

Loss tangent (tanδ) 1GHz |

0.005 |

0.006 |

0.005 |

0.006 |

0.006 |

0.005 |

|

|

UL94 |

HB (0.7mm) |

HB (0.8mm) |

V-0 (1.5mm) 5VB (3mm) |

V-1 (2.0mm) |

V-0 (0.75mm) |

V-1 (0.6mm) |

|

The data listed in this properties table are representative values measured based on the test method.

Other new products such as high dielectric LDS grade for 5G are under development.